Inhouse Storage Solutions

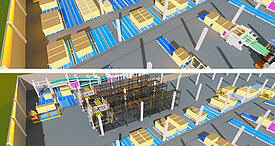

The MINDA Inhouse Storage Solution is ideal for limited space conditions, as it is installed vertically upwards on a small footprint, making full use of the available hall height.

The storage concept for in-house storage involves the individual storage of blocks. This ensures that the drying process of the freshly produced sheet material coming from the corrugator is the same for each block. This provides optimum conditions for further processing of the corrugated board blocks.

The demand for storage concepts behind the corrugator is increasing: While the output of these systems continuously rises, the converting machines can simultaneously produce ever faster. For this demanding process it is necessary to provide the same condition of the corrugated board for the printing and die-cutting operations, which is achieved by an accordingly constant storage time. Thus, there is an increased need for storage capacity to optimally discharge the corrugator on the one hand and to meet the increased demands of the converting machines on the other hand. More corrugated board must be prepared in front of these machines in order to feed them optimally according to the speed.

The inhouse storage solution ensures the perfect interaction with the corrugator by not only providing more storage space in a smaller area, but also by achieving more flexibility. The corrugator can pre-produce specific orders for the warehouse and is thus further decoupled from the converting machines. The single-deep storage within this warehouse allows direct access to each individual block.

The conception of the inhouse warehouse is completely individual according to the local conditions and the customer-specific adaptation to the production. The planning of the respective compartments of the inhouse warehouse is individually adjusted to the necessary dimensions (L x W x H) of the products. Individual dimensions can also be assigned to specific compartments, depending on existing interfering contours of the ceiling.

The shelf compartments can be occupied with single or double loads, so that, for example, a large block can be stored or two small half blocks of half a compartment width can be stored next to each other in one compartment. In combination with a small machine storage as area storage, the highest possible dynamics in the process are obtained.

MINDA storage and retrieval machine

MINDA has developed a storage and retrieval machine specifically for the inhouse storage solution, which is designed for very low construction heights. The storage and retrieval machine moves on two floor rails and does not require an upper guide rail. Thus, the free space under the ceiling offers additional storage capacity, as the existing hall height can be almost completely utilized. The storage and retrieval machine can immerge between roof frames (or other interfering contours) to make use of the entire space. For this purpose, the body of the load handling device is extended beyond the post and this additional height is used for storage and retrieval in the rack. The compartments are reached in both directions by telescopic forks.

Due to the low approach dimension at the bottom, the storage and retrieval machine is optimally adapted to the MINDA conveyor technology. Thus, by using chain conveyors on the storage and retrieval machine, the stacks can also be transferred to the conveyor technology without any need for lifting. In addition, the storage and retrieval machine and the rack structure are independent, so that no lateral forces act on the rack structure, and it can usually be designed with simple lightweight technology. Industrial floor is usually sufficient for the construction of an inhouse warehouse, and no additional foundations are required.

Detailed planning process

In order to develop the best possible solution for the customer, our aim is not just to implement a general standard as a storage solution, but to design a concept that is precisely tailored to the customer's production and makes the best possible use of the available space.

For this purpose, MINDA with its own simulation department provides the corresponding team right from the start of the project considering all conditions for the planning by means of detailed data collection and evaluation. At the beginning, a 3D scan of the existing hall(s) is done on site. This scan results in a virtual image of the hall and the actual situation can be displayed three-dimensionally with all necessary dimensions. Thus, the planned project is visualized right at the beginning and, for example, interference contours can be clearly identified.

In addition to the data from the 3D scan, the simulation department considers the customer's production data from the corrugator. Based on these real data, production can be simulated in advance and bottlenecks can be identified.

A storage concept is then developed according to these details, which considers the output of the corrugator and at the same time bears in mind the customer's product range. MINDA is permanently in close exchange with the customer, as storage capacities can also be planned for the future in order to create a long-term solution.

Conclusion

From planning to implementation of the project, the customer receives everything from a single source at MINDA as a full-service provider in the field of intralogistics. Even with limited space conditions, the inhouse storage solution promises a storage concept, in combination with a partial area storage, which meets the increased production requirements in terms of flexibility and capacity.